OEE Test

This Test stores OEE data.

The OEE Test is not available in GS Essential.

Test Settings

Required Settings for this Test are:

Label

The label displayed above this Test.

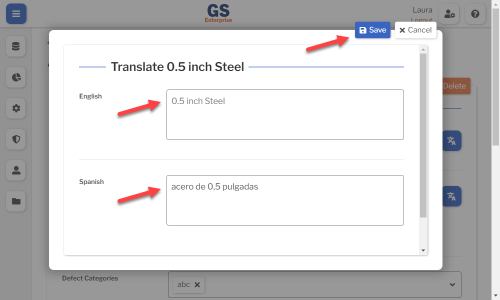

You can translate this into another language (Spanish or English).

Visible

When this Test is not Visible, it will not be displayed to the data entry inspector.

Enabled

When Enabled, the data entry inspector can set or change its value.

If you use Inspection Scripts to set this Test's value, you might want to clear this checkbox so that the data entry inspector can't set or change its value.

Script ID

This is used by Inspection Scripts to identify this Test.

Required

The data entry inspector cannot Submit the Sub-Inspection if required data fields are blank.

This depends on what you select for the Track Availability, Track Performance, Track Quality, and Enable Total Parts Settings.

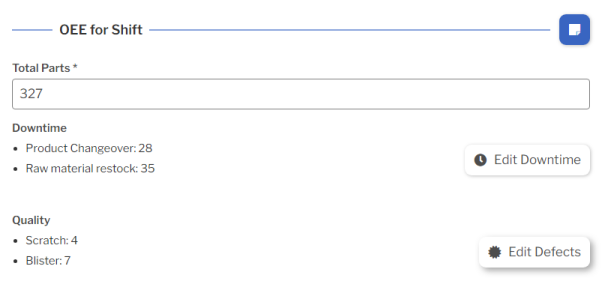

Track Availability

- If set to Enter Downtime with Reasons, you must also set the Availability Defect Category to a Defect Category that contains Availability defects.

- During data entry, the inspector can enter the Downtime minutes caused by each Availability defect.

- When the Sub-Inspection is Submitted, GS will store an additional DMS data record for this Availability defect data, using the Availability Process Override and Availability Part Override.

- This lets you use DMS analysis tools to drive down Availability defects.

- If set to Enter Available Time, the inspector can enter the Available Time in minutes.

- To avoid tracking Availability and Downtime, set this to Do Not Track.

Track Performance

If selected, you must also set the Cycle Time to the number of minutes required to produce one part under ideal conditions.

Track Quality

- If set to Enter Bad Parts with Defects, you must also set the Quality Defect Category to a Defect Category that contains Quality defects.

- During data entry, the inspector can enter the number of bad parts attributed to each Quality defect.

- When the Sub-Inspection is Submitted, GS will store an additional DMS data record for this Quality defect data, using the Quality Process Override and Quality Part Override.

- This lets you use DMS analysis tools to drive down Quality defects.

- If set to Enter Good Parts, the inspector can enter the number of Good parts produced.

- To avoid tracking Quality, set this to Do Not Track.

Availability Defect Category

Select the Defect Category that contains the Availability Defects.

During data entry, the inspector can enter the Downtime minutes caused by each Availability defect.

This Setting is only used if Track Availability is set to Enter Downtime with Reasons.

Availability Process Override

Choose the Process used to store Availability defect data.

If not set, the current Process will be used.

This Setting is only used if Track Availability is set to Enter Downtime with Reasons.

Availability Part Override

Choose the Part used to store Availability defect data.

If not set, the current Part will be used.

This Setting is only used if Track Availability is set to Enter Downtime with Reasons.

Scheduled Time (Minutes)

The minutes of Scheduled Time for the data collection period (typically an hour or a work shift).

This Setting is only used if Track Availability is set to Enter Downtime with Reasons or Enter Available Time.

Cycle Time

The number of minutes required to produce one part under ideal conditions.

This Setting is only used if Track Performance is enabled.

Quality Defect Category

Select the Defect Category that contains Quality defects.

During data entry, the inspector can enter the number of bad parts attributed to each Quality defect.

This Setting is only used if Track Quality is set to Enter Bad Parts with Defects.

Quality Process Override

Choose the Process used to store Quality defect data.

If not set, the current Process will be used.

This Setting is only used if Track Quality is set to Enter Bad Parts with Defects.

Quality Part Override

Choose the Part used to store Quality defect data.

If not set, the current Part will be used.

This Setting is only used if Track Quality is set to Enter Bad Parts with Defects.

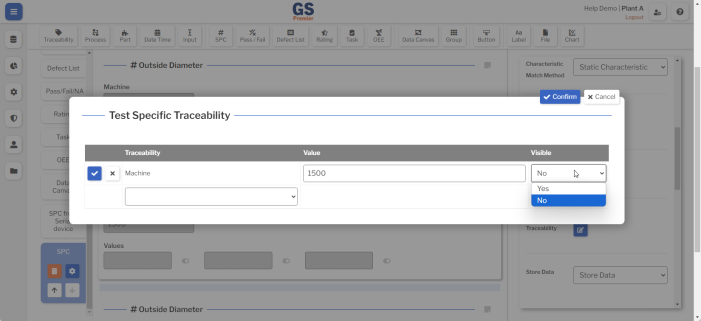

Test Specific Traceability

This Setting lets you set a Traceability value for only this Test on the Sub-Inspection.

If used, this Traceability value will override any other value set for this Traceability via a Traceability Test, User Setting, and so forth. For details, see Automatically setting Traceability values.

To set Test Specific Traceability:

- Select which Traceability to set.

- Set a Value for the Traceability, or leave the Value blank to let the data entry inspector enter the Value.

- Choose whether to make this Traceability Visible or hide it from the data entry inspector.

- If desired, you can add more Test Specific Traceabilities using the steps above.

- Select the Confirm button

when finished.

when finished.

Store Data

If using Inspection Scripts for this Inspection, you might want to use this Test to hold intermediate values but not store them in GS.

Your options are:

- Store Data (the default)

- Do Not Store Data — Use all of the GS features for this Test, and do not store its data in GS.

- Bypass Validity and Do Not Store — Turn off all GS validation checks for this Test, and do not store its data in GS.

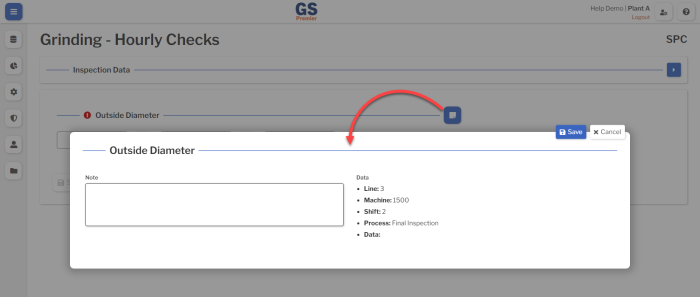

Note Button

This Setting affects the Note button  for this Test.

for this Test.

It determines whether GS uses the Inspection Setting, requires the data entry inspector to enter a Note before submitting a Sub-Inspection, makes the Note optional, or hides the Note button.

When available, the data entry inspector can select this button and enter a text Note for this Test.

Alert

You can choose an Alert that will automatically send a text message or email if this Test detects a real time failure.

Enable Total Parts

When Enabled, the data entry inspector can set or change the Total Parts during data entry.

If using Inspection Scripts to set the Total Parts for this Test, you might want to clear this checkbox so that the data entry inspector can't change this value.

Border

Add borders to the edges of this Test.

Freeze Test

If this Test is placed on the same row as a longer Test, it will not scroll off the screen until the longer Test scrolls off the screen.

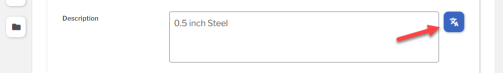

Translating text into another language

To translate a text field into another language (Spanish or English), select its Translate  button.

button.

Enter your translated text, then select the Save button at the top or bottom of the window.

For more information on translating text fields and changing the language displayed to the user, see Custom Translations.